How to Find the Correct way for a Screen Printing Job?

1, There may be one kind of emulsion. The reality is that all that is emulsified by quality producers are working. For instance, if you print with water-based ink and do not use an emulsion specifically formulated for this purpose, you can have problems. This is a simple fix: swap the product simply for a more acceptable emulsion.

2, Drying Screens Properly:

The emulsion consists mainly of liquid; a 40% solid emulsion consists of 60% water, and before exposure, the humidity needs to evaporate from the stencil.

The excess water can prevent the stencil from curing when the coated screen is not fully drained, causing many problems, such as loss of durabilities, premature press breakdown, poor quality, inadequate water or solvent, and grips.

In addition, this excess water blocks the cross-linking of the stencil during the process of exposition. In diazo and dual-cure products, this is especially true. Even photopolymer emulsions can be completely healed after growth. You have to monitor the atmosphere by keeping the drying area as dry as possible to ensure best practice in screen drying.

So an excellent drying cabinet will be more important.

How to Find the Correct way for a Screen Printing Job?

1, There may be one kind of emulsion. The reality is that all that is emulsified by quality producers are working. For instance, if you print with water-based ink and do not use an emulsion specifically formulated for this purpose, you can have problems. This is a simple fix: swap the product simply for a more acceptable emulsion.

2, Drying Screens Properly:

The emulsion consists mainly of liquid; a 40% solid emulsion consists of 60% water, and before exposure, the humidity needs to evaporate from the stencil.

The excess water can prevent the stencil from curing when the coated screen is not fully drained, causing many problems, such as loss of durabilities, premature press breakdown, poor quality, inadequate water or solvent, and grips.

In addition, this excess water blocks the cross-linking of the stencil during the process of exposition. In diazo and dual-cure products, this is especially true. Even photopolymer emulsions can be completely healed after growth. You have to monitor the atmosphere by keeping the drying area as dry as possible to ensure best practice in screen drying.

So an excellent drying cabinet will be more important.

3. Without stencil you lose detail:

Detail and resolution are the roles of the stencil. Based on the volume and thickness of the wire, you can determine the amount of ink required.

The quantity of stencil material on the panel is known as mesh emulsion, which is measured as an emulsion degree over the mesh thickness. The moderate thickness will make your printing effect better. To achieve the right thickness, you require proper methods of coating. Second, maintain a smooth round edge of your manual coater.

Emulsion of scrapes with a smooth surface. The round edge covers the mesh, fills the mesh openings. Proper methods of coating will proceed to the end of the coating cycle on the squeegee side.

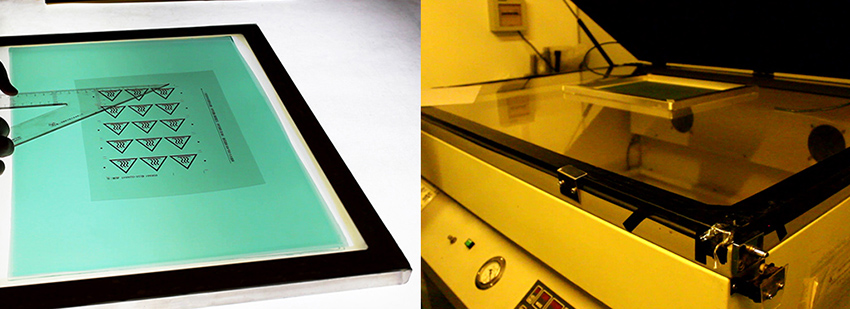

4. How does Image Exposure work?

The light must be single or in a column to create this crisp shadow. Collimate light is a form of light found in single-point lights such as a metal halide or LED point.

In comparison to a multi-faceted light, this collimated light permits the desired resolution like fluorescent pipes.

Conclusion:

The right emulsion is the secret to a successful and efficient printing process for your shop.

Using the right and professional screen printing facilities to make sure the screen operation is running smoothly.

3. Without stencil you lose detail:

Detail and resolution are the roles of the stencil. Based on the volume and thickness of the wire, you can determine the amount of ink required.

The quantity of stencil material on the panel is known as mesh emulsion, which is measured as an emulsion degree over the mesh thickness. The moderate thickness will make your printing effect better. To achieve the right thickness, you require proper methods of coating. Second, maintain a smooth round edge of your manual coater.

Emulsion of scrapes with a smooth surface. The round edge covers the mesh, fills the mesh openings. Proper methods of coating will proceed to the end of the coating cycle on the squeegee side.

4. How does Image Exposure work?

The light must be single or in a column to create this crisp shadow. Collimate light is a form of light found in single-point lights such as a metal halide or LED point.

In comparison to a multi-faceted light, this collimated light permits the desired resolution like fluorescent pipes.

Conclusion:

The right emulsion is the secret to a successful and efficient printing process for your shop.

Using the right and professional screen printing facilities to make sure the screen operation is running smoothly.

Post time: Jun-03-2019